What is Economic Order Quantity Inventory Management (EOQ)

In any business that buys and stores products, ordering the right amount of stock is critical. Order too much, and your money sits idle in excess inventory. Order too little, and you risk losing sales due to stockouts. Economic Order Quantity Inventory Management (EOQ) is the tool that helps you find that perfect balance — the exact amount to order so your costs are minimal, and your customers are satisfied.

Understanding Economic Order Quantity Inventory Management

Economic Order Quantity Inventory Management is a calculation used by businesses to determine the ideal order size for inventory replenishment. It’s a core part of inventory management, aiming to minimize total costs by balancing ordering costs (expenses for placing and processing orders) and holding costs (expenses for storing stock).

In simple terms, EOQ tells you how much to order and when to order it so you spend less and operate more efficiently. This method applies whether you sell furniture, auto parts, food products, or raw materials.

Why EOQ Matters in Inventory Management

Efficient inventory management ensures smooth operations, healthy cash flow, and satisfied customers. Economic Order Quantity is vital because it directly affects:

- Profitability – By avoiding overstocking, you reduce storage costs and free up capital.

- Customer service – Having the right stock available means orders are fulfilled on time.

- Operational efficiency – Predictable ordering cycles help optimize supplier relationships and logistics.

Without EOQ, businesses often end up overinvesting in stock or running into shortages — both costly mistakes.

How Economic Order Quantity Inventory Management Works

EOQ works by calculating the order quantity where ordering costs and holding costs are at their lowest combined total. Here’s the process in simple steps:

- Determine annual demand for the product.

- Calculate ordering costs — the expense each time you place an order (admin work, shipping fees, processing).

- Calculate holding costs — the cost of storing one unit for a year (warehouse rent, insurance, depreciation).

- Plug these numbers into the EOQ formula.

When done correctly, you’ll know exactly how many units to order at each replenishment to keep total costs low.

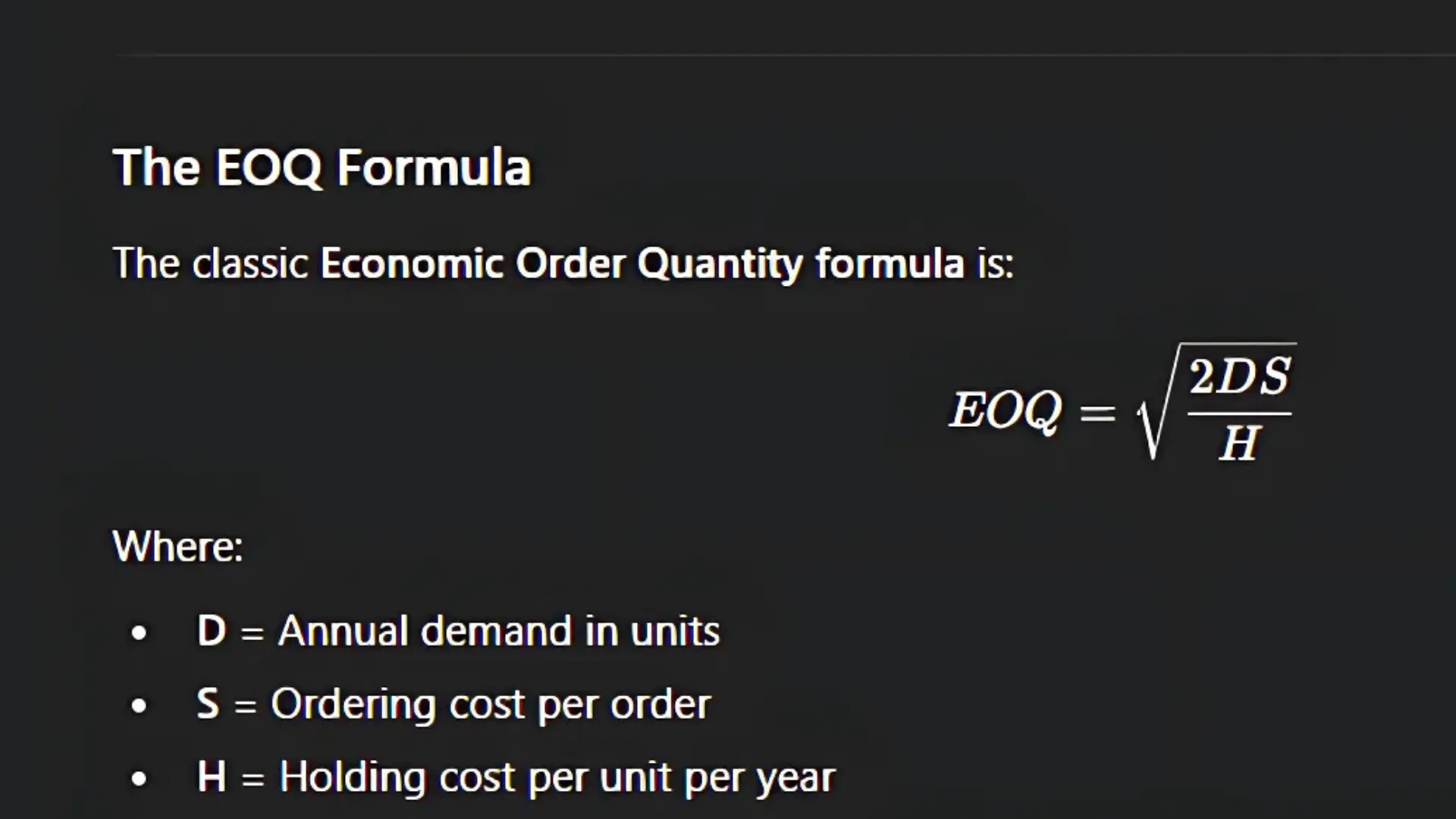

The EOQ Formula

This formula assumes demand is consistent throughout the year and ordering/holding costs remain stable.

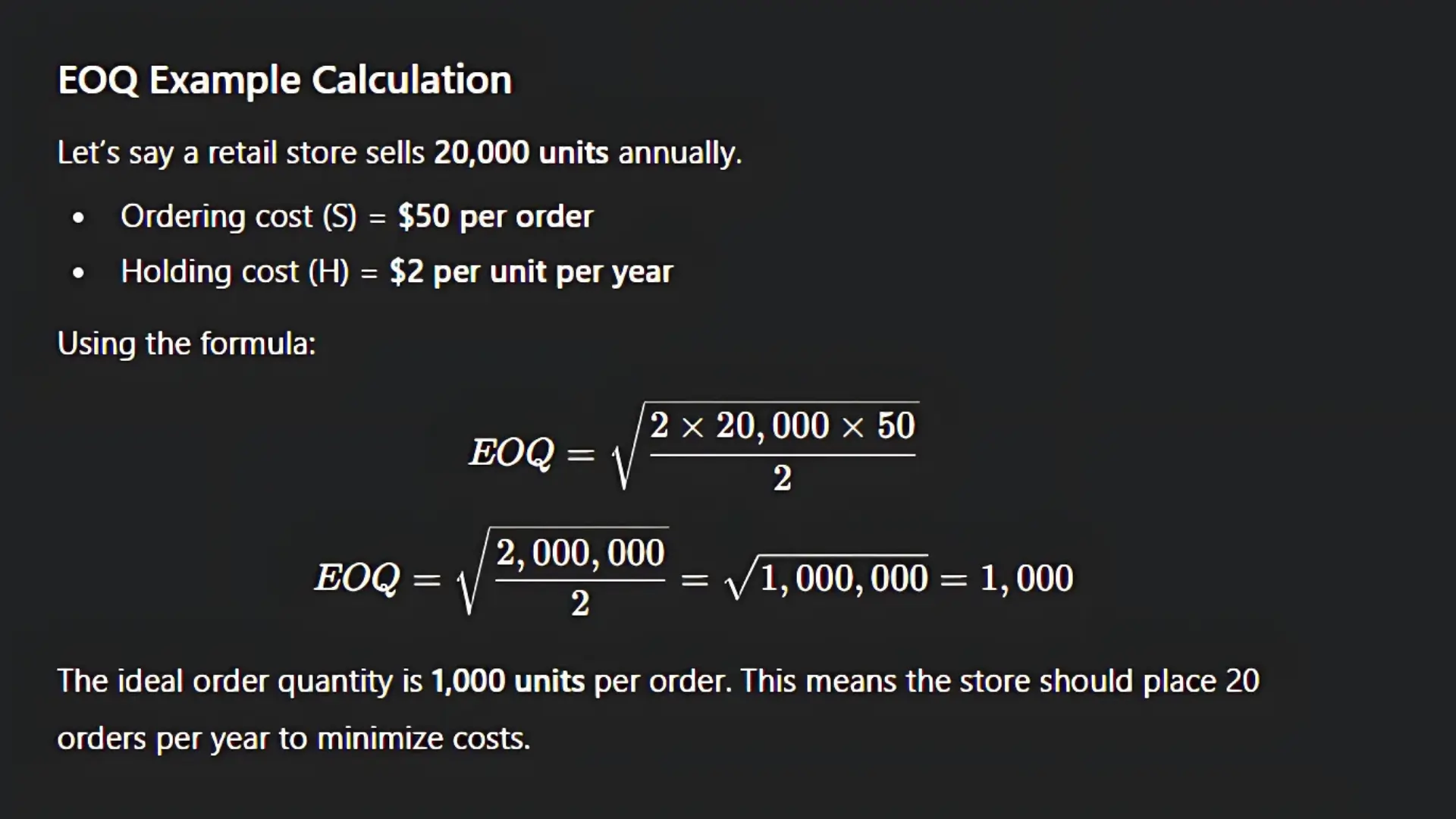

EOQ Example Calculation

Benefits of Economic Order Quantity Inventory Management

Implementing EOQ in your inventory management strategy offers several benefits:

- Improved order fulfillment – The right stock at the right time means fewer delays and happier customers.

- Lower storage costs – Reduced excess inventory saves on rent, utilities, and insurance.

- Reduced waste – Particularly important for perishable goods, EOQ helps prevent obsolete stock.

- Better cash flow – Less money tied up in inventory frees resources for marketing, R&D, or expansion.

- Supplier discounts – Well-planned orders can help you take advantage of bulk purchase deals.

Challenges and Limitations of EOQ

While Economic Order Quantity Inventory Management is powerful, it’s not without limitations:

- Data accuracy – The calculation is only as good as the numbers you put in. Poor demand forecasts or outdated costs will distort results.

- Seasonal demand – EOQ assumes constant demand, so it needs adjustment for seasonal peaks and drops.

- Rapid growth – In fast-scaling businesses, EOQ must be recalculated often to remain relevant.

- Variable costs – Changes in ordering or holding costs can impact the formula’s accuracy.

EOQ in Road Transportation and Logistics

For businesses in road transportation, EOQ plays a unique role. Freight costs, delivery schedules, and vehicle capacity directly influence ordering costs. Large, infrequent orders may lower transport expenses but increase holding costs. Conversely, frequent small shipments can keep inventory lean but raise transportation costs.

By applying EOQ principles, logistics managers can determine the shipment size that balances storage expenses and freight costs — reducing total operating costs and improving delivery reliability.

Key Takeaways for Businesses

- EOQ isn’t just a formula — it’s a decision-making tool.

- It works best in stable demand environments but can be adapted for changing conditions.

- Combining EOQ with modern inventory management systems improves accuracy and saves time.

- Businesses in manufacturing, retail, and logistics can all benefit from its cost-cutting potential.

Conclusion

Economic Order Quantity Inventory Management (EOQ) is more than a theoretical model. It’s a practical, proven method for lowering costs and ensuring you have the right products at the right time. Whether you run a small retail store or manage a large supply chain, understanding EOQ can sharpen your inventory strategy and boost your bottom line.

If your business relies on stock to keep operations moving, EOQ isn’t optional — it’s essential.

1 thought on “What is Economic Order Quantity Inventory Management (EOQ)”